Titus Cycles Factory Tour!

Most bikes are built and assembled overseas, as most things are now. There a quite a few smaller producers of bikes here in the US. However, only a few of them are willing to take the time to do custom sizing, individual design and handcraft their frames. Titus Cycles in Tempe Arizona is one of them. I've read a number of great things about this companies products and once I test rode one, I knew I had to have one! Mike, the owner of the bike shop I race for, Trails-Edge Cyclery (www.trails-edge.com) is also a big fan of the company and their products. He has always had positive things to say about the customer service they provide. If you can provide great products and back them up with great customer service too, I'm sold!

I was impressed from the start with my bike order. I had the opportunity to talk with the designers and owner about my riding style, what I was looking for performance wise and the design and geometry. They kept us updated, via the bike shop, on the progress and the frame was delivered as promised. The folks over at Titus claims to have an open door policy regarding stopping in for a tour of their facility. Since Laura and I are currently camping 3 miles from them, here in Tempe, we decided to put them to the test!

The building is very nondescript on the outside. Not sure what I expected, maybe a parking lot full of cars with racks of shiny new Titus' on them? People test riding rigs around the building? Oh, but what wonder and amazement await inside!

Walk into lobby and you get what you expect, bikes, frames and offices! However, big disappointment as I look around, people are (gasp) actually working?! The phones are ringing, vendors are waiting, welding, building up, packing and shipping! So much for the dream of working in the bike business and just riding bikes all day ;)

First stop, the machine shop where the raw tubing is prepared for fabrication.

Here we have raw aluminum and ti tubes waiting to be formed into swingarms, head tubes, down tubes chain stays etc....

Each and every tube gets deburred, polished, shaped and welded by hand. Very impressive!

Once the tubes are sized and preped for assembly, its off to the welding room. They didn't have any bikes actually being assembled during our visit. They were doing finishing work, cable guides and bottle mounts. Here is a pic of the swing arm room (rear end of the bike for our non biking readers).

New for 2006, upper portion of the rear swing arm is carbon fiber. I could not convince them to upgrade my bike!! They claim all of this stock is spoken for......sure!

Once all the pieces come together as a frame, its time for quality inspection and decals!

All of these ti hardtails (drool!) are waiting in line for their decals!

Here are moto-Lite front triangles waiting for rear ends!

Here is a recently completed Moto-Lite. If I had the cash, this would probably be the ultimate trail bike out here in the west!

Here is an exogrid frame welded together for display without the carbon fiber inserts. They remove up to 1/3 of ti tube and replace it with carbon fiber. This frame was extremely flexible around the laser cut out areas. Really amazing technology!

Finally, the finished product! Here is my 2005 Exogrid Racer X all tuned and shined up ready to roll.

Here I am on the trails in Phoenix! If your in the area, stop by Titus and get the tour. They are a great group, willing to show you around, even if you don't own a Titus.......yet!!

-Rich-

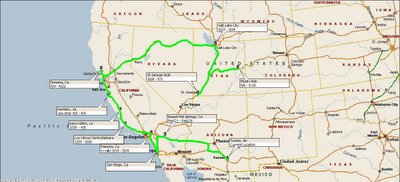

In the past 3 days, we've had over 100 visits to our blog and around 45 unique visitors! We're even going global, we have two readers in Australia! I've mapped most of the unique visitors in the map, but its starting to get crowded!

In the past 3 days, we've had over 100 visits to our blog and around 45 unique visitors! We're even going global, we have two readers in Australia! I've mapped most of the unique visitors in the map, but its starting to get crowded!